MAPerformance

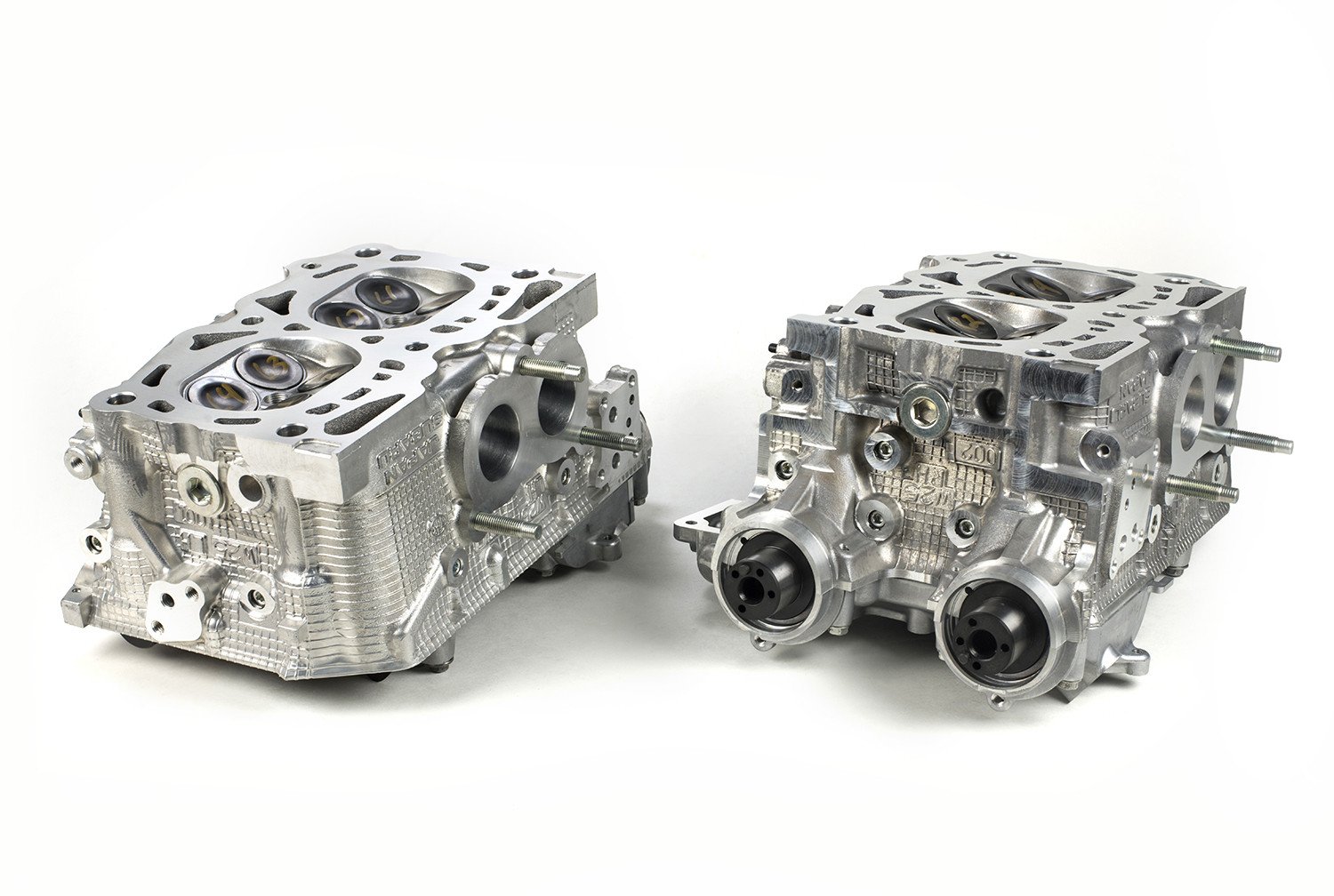

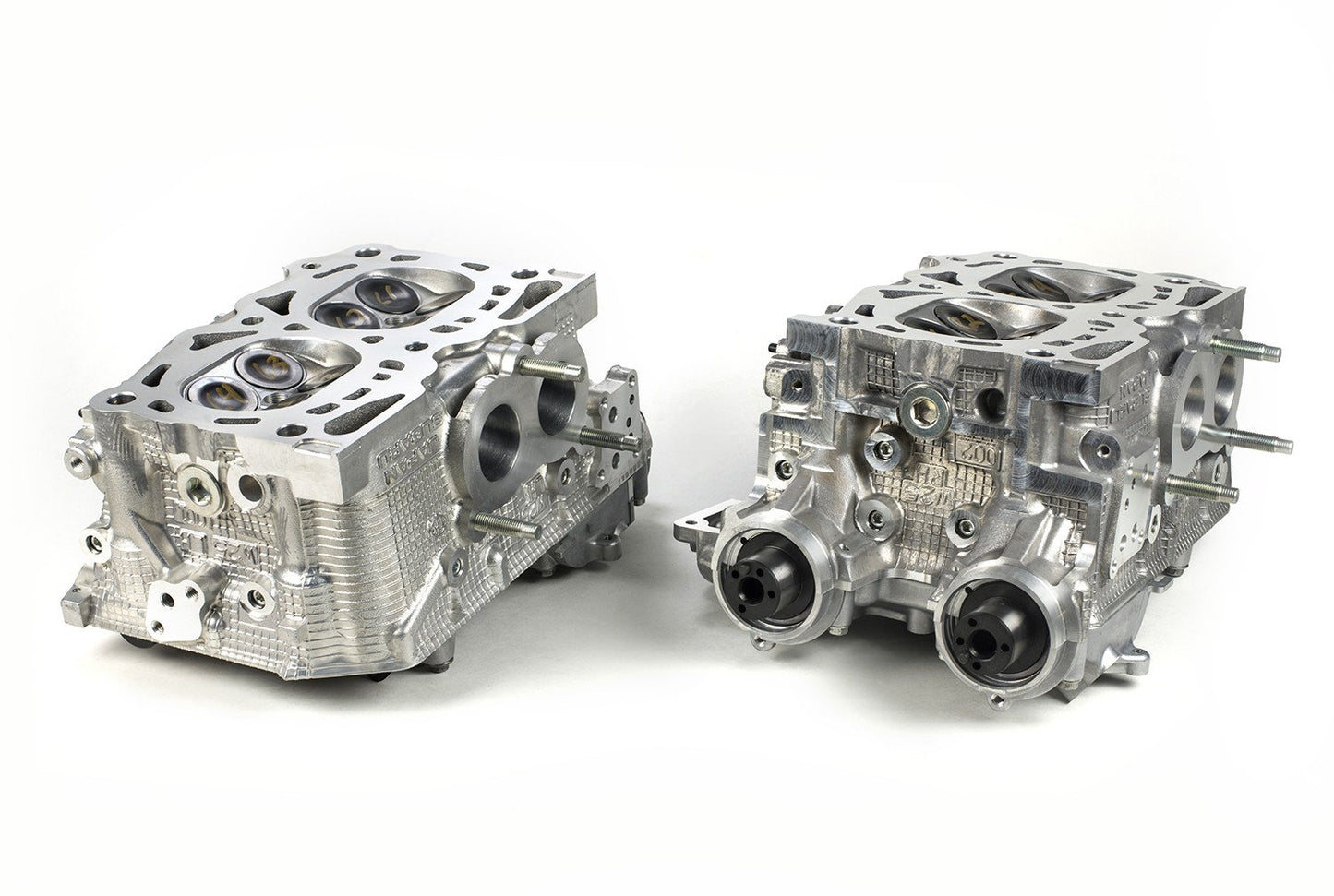

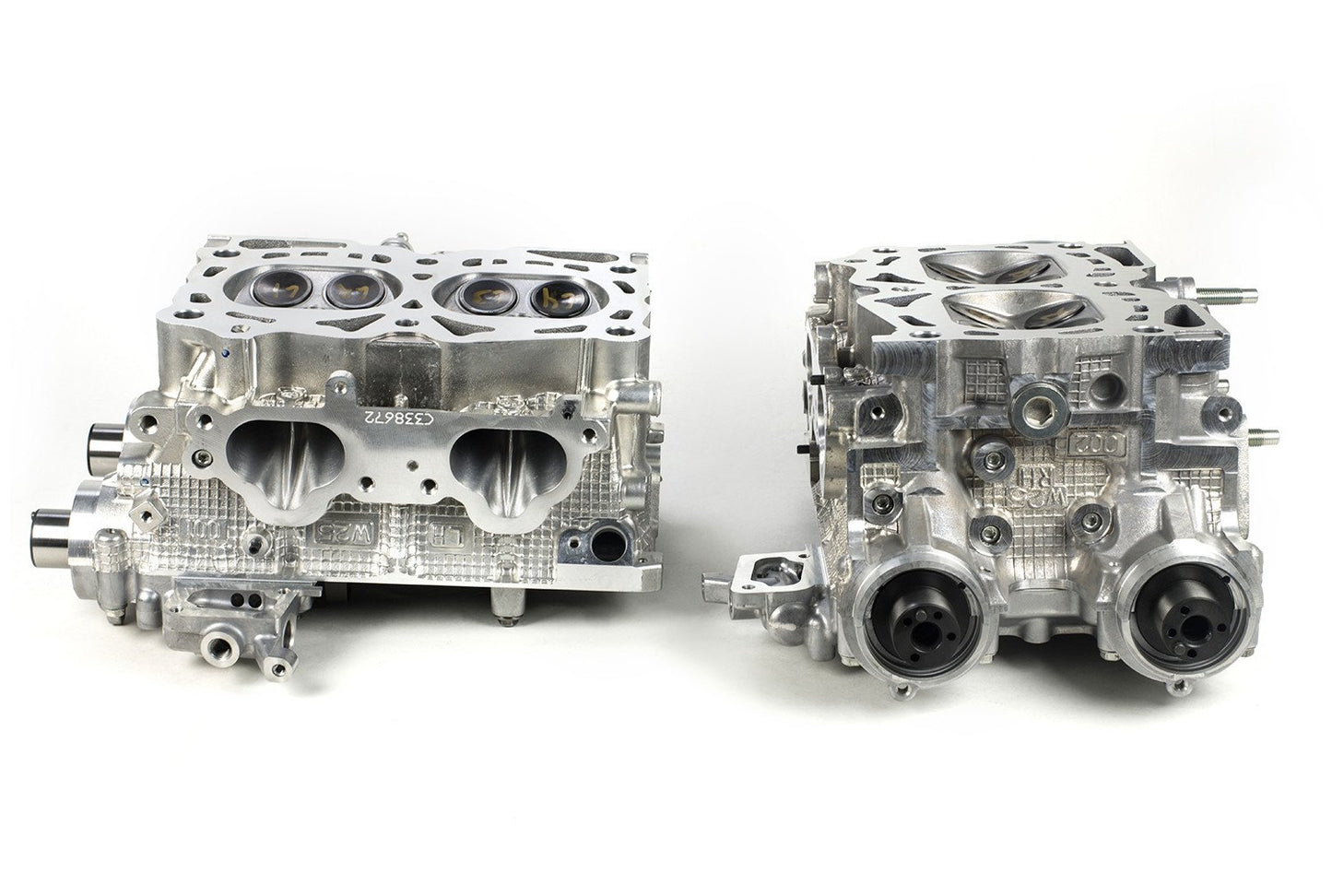

MAP Stage 3 Cylinder Head Preparation (Subaru)

MAP Stage 3 Cylinder Head Preparation (Subaru)

SKU: MAP SUB-CHS-S3-0205WRX

Need it ASAP? Check stock or lead times, please give us a call at 801-769-6929 or reach out to one of our sales reps!

Couldn't load pickup availability

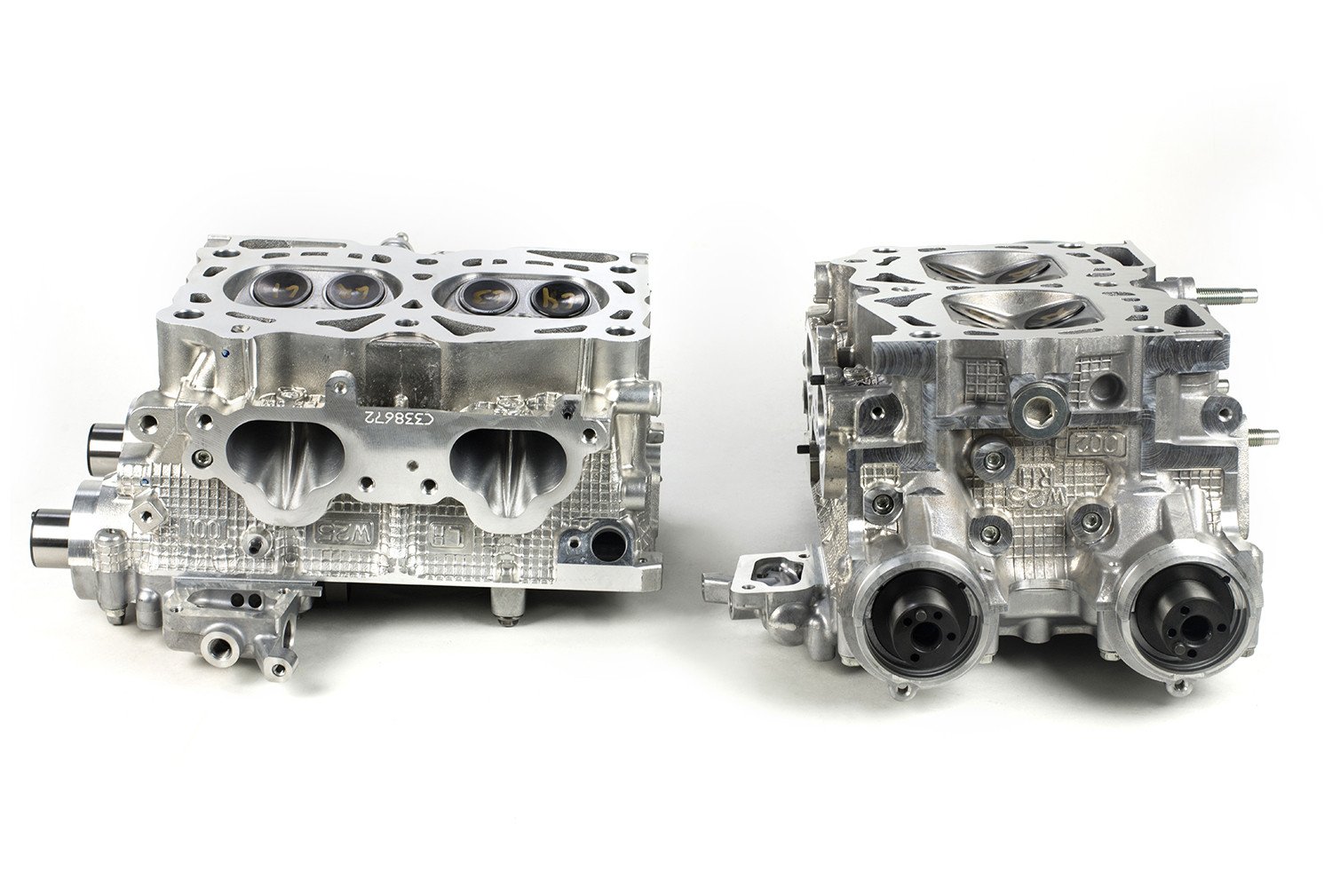

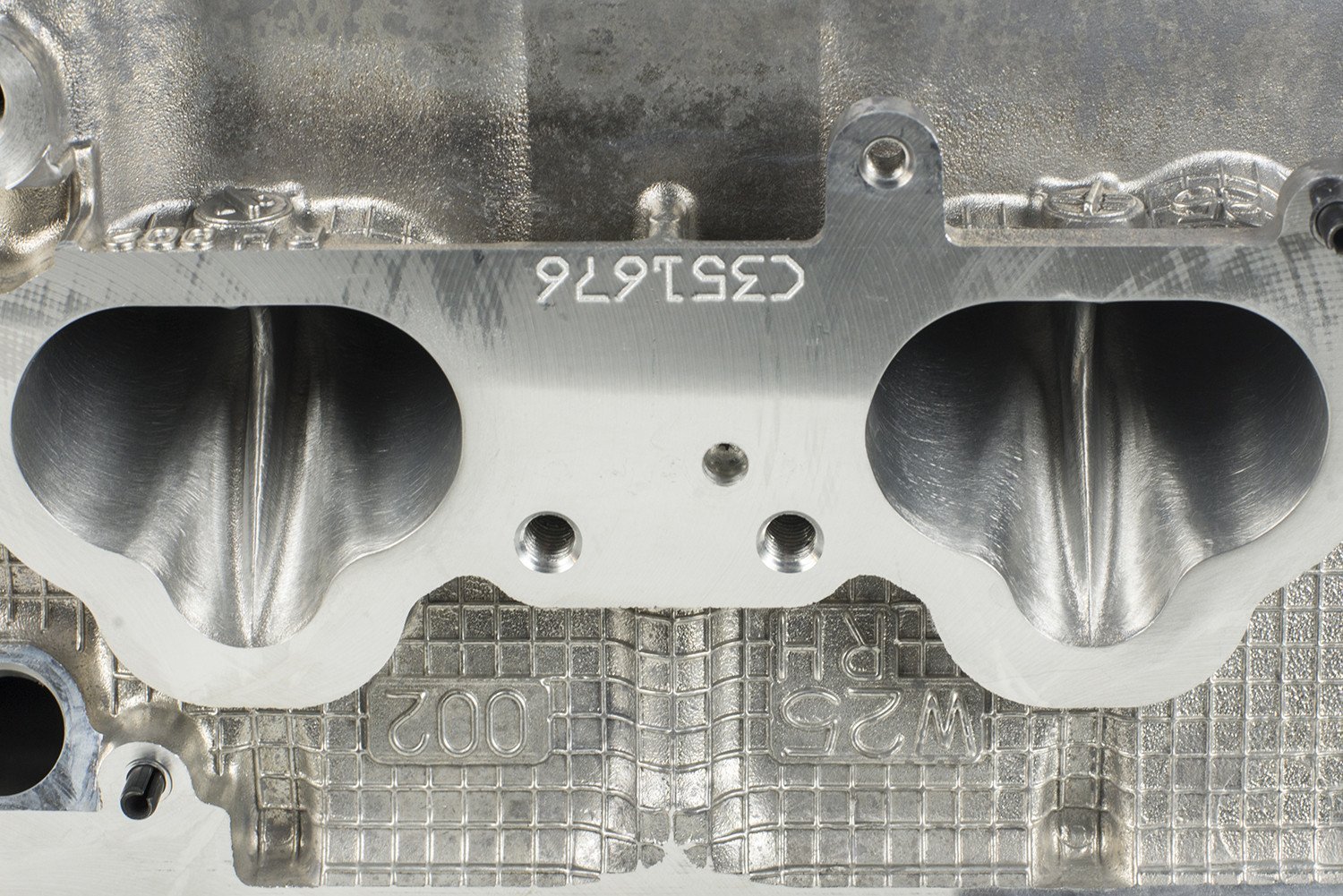

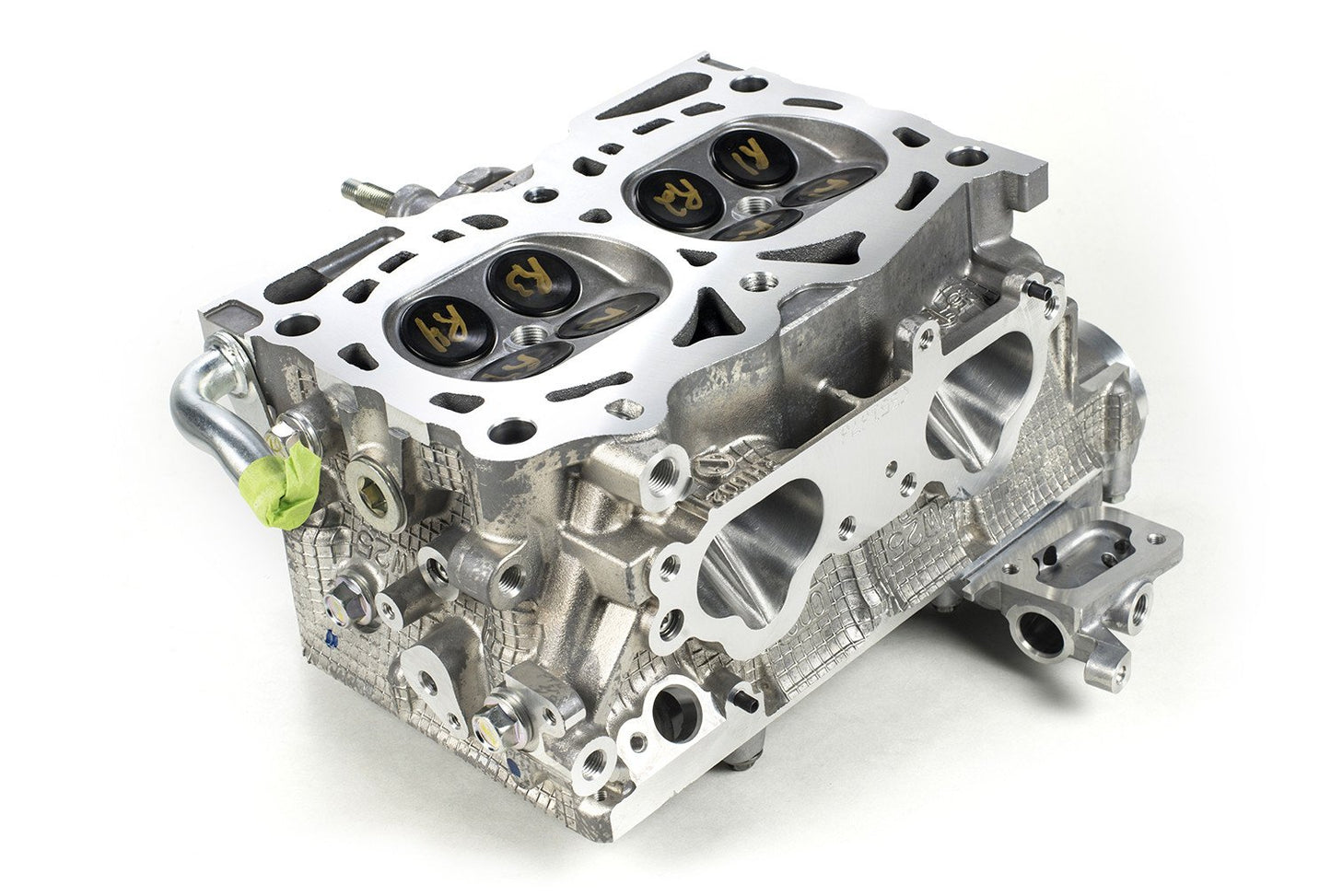

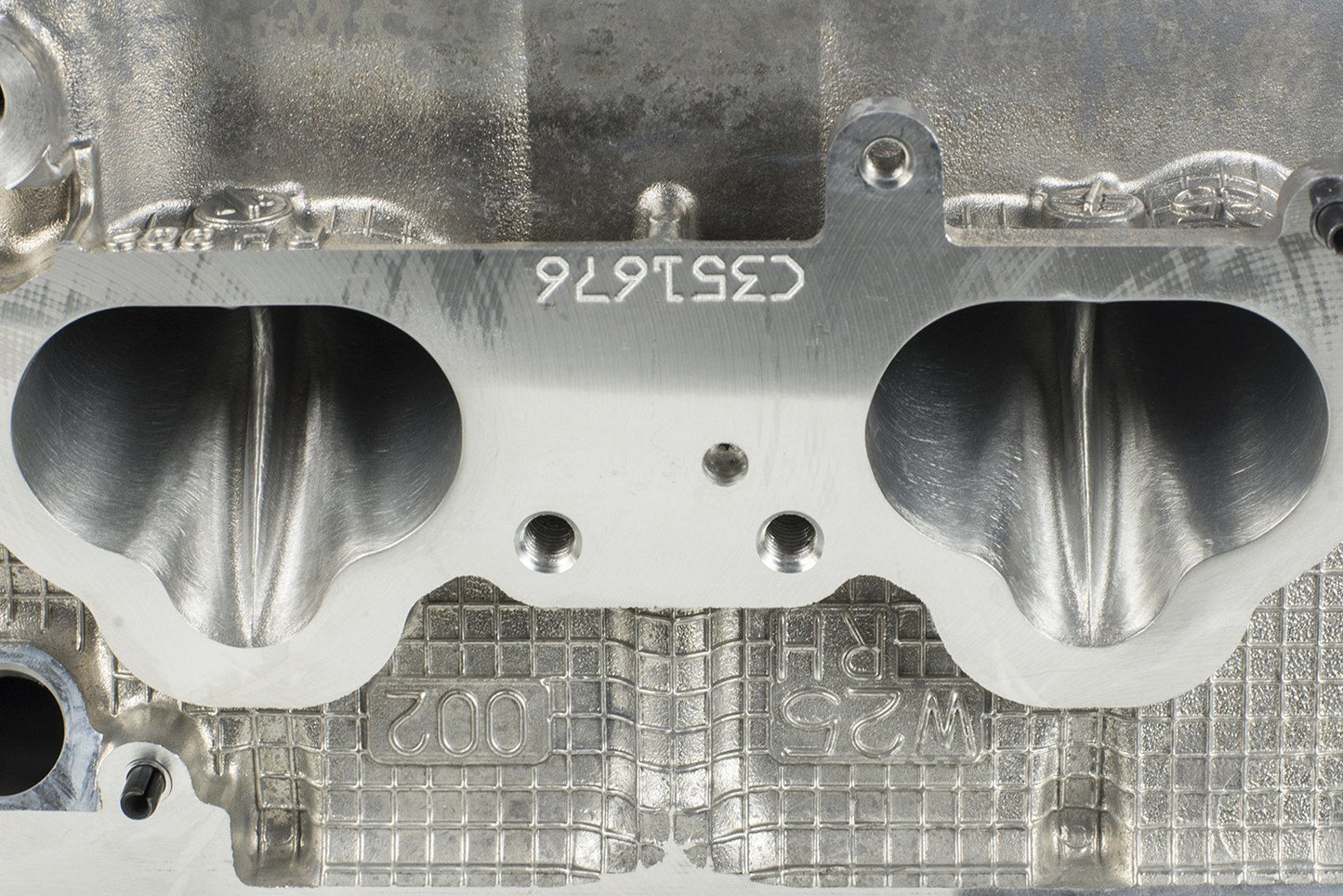

The MAP Stage 3 service porting & polishing service starts with cleaning up the casting flash in both the intake and exhaust ports, improving bowl to seat blending, and unifying all of the ports to ensure even flow to each cylinder. Then we take it one step further with additional shaping of the bowls for even more airflow. Combine this with our world class machine work and you've got what we feel is the absolute best street/strip cylinder head on the market!

Included Services

- Clean / Hot Tank

- Visual Evaluation / Inspection

- Deck Resurface to High Performance RA Specs

- Proprietary MAP 5 Angle Radius Valve Job

- MAP Stage 3 Porting / Polishing

- Final Assembly

- Outbound Shipping via Fedex Ground service

Valvetrain Components

We understand that customers looking for cylinder head service may have already obtained some, if not all, of their valvetrain components. We also understand that many customers are looking to purchase a complete cylinder head package from one reliable source. As such, we will provide the option to purchase valvetrain components to be included with your cylinder head service as seen below. If you already have the component in question and plan to send it in for your cylinder head service, simply choose "Customer Supplied." As a side note, shims/buckets can usually not be reused, so will need to be replaced on a case-by-case basis. You will be notified of what is needed and the cost associated.

Why Choose MAP Machining Services?

We utilize a Serdi seat and guide machine that provides us with some of the industry's finest valve jobs. We not only cut seats for the non performance market, but have also designed specific cutters that we use in all our modern 4 valve heads. Every head is also vacuum checked after each seat is cut to ensure that no head leaves with a poor sealing valve. We would then typically set and adjust the installed valve tip height to our specs to ensure proper valve train geometry is maintained.

We also have a resurfacing machine that provides a superior RA, or finish, on both cast and aluminum blocks and heads, which is crucial for proper head gasket sealing in modern engines. Ours uses the CBN cutters and provides a superior finish to the older, multi-cutter systems that many shops still use.

Please note that this product is built to order. Based on fluctuations in demand build times may vary throughout the year. Please contact an MAP sales representative for current estimations.

Share

Subscribe to our emails

Be the first to know about new collections and exclusive offers.